Investigation and assessment of hydrogen-induced corrosion (SSCC, SCC, HTHA, HIC) in various types of steels.

Electrochemical corrosion tests.

Weight loss and salt spray tests.

Identification of on-siteized corrosion types.

Research tests.

Evaluation of material corrosion resistance using immersion methods:

Pitting Test

Crevice Test

Critical Pitting Temperature

Critical Crevice Temperature

Assessment of anodes (MMO) following the standard (NACE TM 0108).

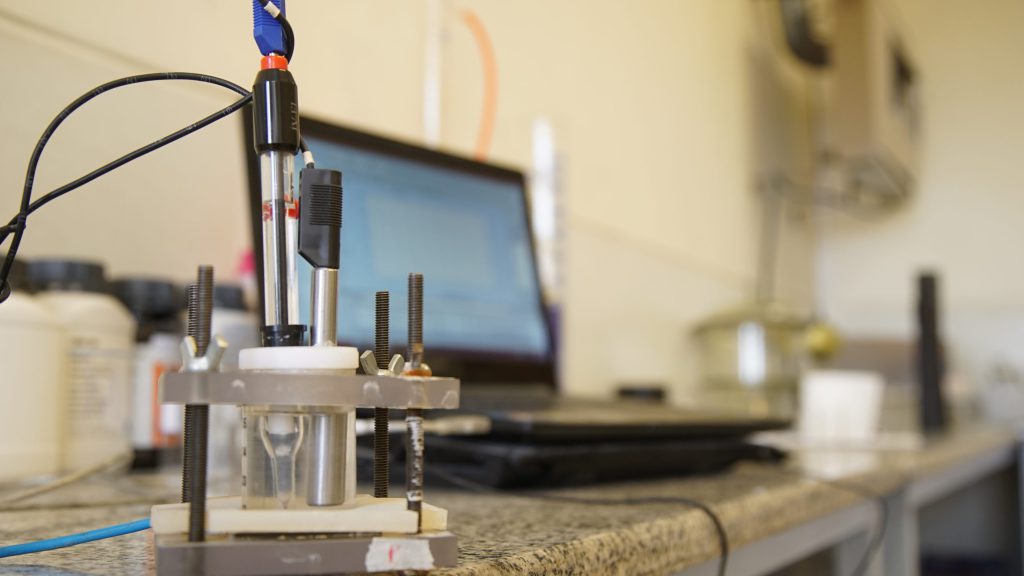

Advanced electrochemical analysis tests:

The Scanning Electrochemical Microscope (SECM).

Scanning Vibrating Electrode Technique (SVET).

Scanning Kelvin Probe (SKP).

On-site electrochemical impedance spectroscopy (LEIS).

Scanning Droplet System (SDS) with 3, 5, 4, 2 electrodes.

Surface topography/optical surface profiler (OPS).

Electrochemical tests using methods such as:

EIS (Electrochemical Impedance Spectroscopy).

Noise.

Tafel.

LPR (Linear Polarization Resistance).

Cyclic Voltammetry.

HIC Test:

Conducted over a 96-hour time period.

Complies with the NACE TM0284 standard.

Analysis of the causes of industrial component failures.

Estimation of the remaining service life of industrial components.

Analysis of corrosion causes in components used in the petrochemical, oil, and gas industries.

SSCC Test (Sulfide Stress Corrosion Cracking):

Evaluation of material resistance to stress corrosion cracking under tensile conditions.

Simulation of real-world environments.

Conducted over a 720-hour time period.

Complies with the NACE TM0177 standard.

Utilizes a specialized chamber (chamber).